DTF (Direct-To-Fabric) Printing is a cutting-edge technique revolutionizing textile graphics by printing vibrant, high-quality designs directly onto fabrics without intermediate steps. This method streamlines production, reduces waste, and offers environmental benefits, making it an attractive choice for custom transfers and sustainable textile production. By eliminating setup costs and complex machinery, DTF enables small businesses to create personalized designs with precise placement of graphics and text on garments. The process involves heating and peeling special inks directly onto fabrics for a smooth finish and accurate color representation. Key factors for achieving vibrant prints include high-resolution design files, compatible fast-drying inks, and proper color adjustments based on fabric color.

“Unleash the power of vibrant, visually stunning fabric designs with DTF (Direct-to-Fabric) printing. This innovative technology is revolutionizing textile graphics, offering a dynamic alternative to traditional methods. In this article, we explore the benefits and best practices of DTF Fabric Printing. From its ability to produce rich, durable colors to its versatility across various applications, DTF is the game-changer it promises to be. Discover how experts are recommending this method for everything from apparel to home décor.”

- Understanding DTF Fabric Printing: A Revolution in Textile Graphics

- Benefits of DTF Over Traditional Methods: Why Experts Prefer It

- Best Practices and Applications for Achieving Vibrant DTF Prints on Fabric

Understanding DTF Fabric Printing: A Revolution in Textile Graphics

DTF Fabric Printing represents a significant leap forward in textile graphics, offering a revolutionary approach to printing on various fabrics. The acronym stands for Direct-To-Fabric, indicating a direct application method that skips the intermediary steps often used in traditional printing processes. This cutting-edge technique allows designers and manufacturers to produce vibrant, high-quality prints on a wide range of materials, from cotton tees to performance wear.

By eliminating the need for costly screens or plates, DTF for Apparel streamlines production, making it an attractive option for custom dtf transfers. Its precision and versatility enable intricate designs with rich colors and fine details, ensuring that every garment becomes a canvas for artistic expression. The process is not only efficient but also environmentally friendly, as it minimizes waste compared to traditional screen printing methods, making it a preferred choice for those who prioritize sustainability in their textile production.

Benefits of DTF Over Traditional Methods: Why Experts Prefer It

The advent of Direct to Fabric (DTF) printing has revolutionized the textile industry, offering a superior alternative to traditional methods. One of the key advantages of DTF is its ability to produce vibrant and detailed prints on various fabrics, ensuring colors remain rich and lasting even after multiple washes. This technique eliminates the need for expensive set-up costs and complex equipment typically associated with traditional printing methods, making it an attractive option for small businesses and entrepreneurs looking to create custom designs.

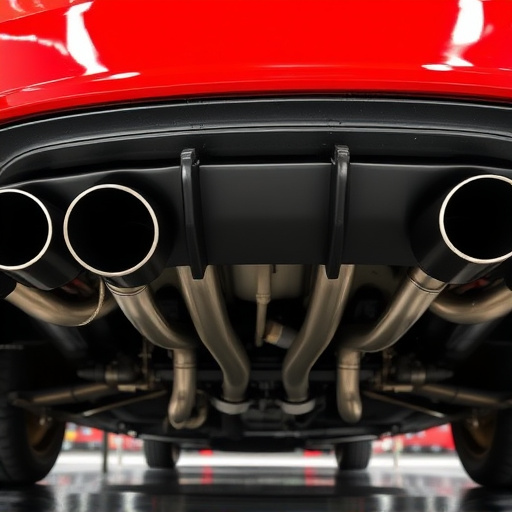

Additionally, DTF allows for precise placement of graphics and text on garments, enabling the creation of unique, personalized items. The process involves applying a special ink directly onto the fabric using a heated press, followed by a quick peel to reveal the printed design. This method, often referred-to as cold peel DTF transfers, ensures a smooth finish and accurate color reproduction, making it ideal for creating custom DTF printing for t-shirts and other textiles. Experts prefer DTF due to its efficiency, cost-effectiveness, and versatility in catering to diverse design needs, particularly when crafting custom dtf transfers.

Best Practices and Applications for Achieving Vibrant DTF Prints on Fabric

To achieve vibrant DTF fabric prints, it’s essential to follow best practices tailored for this unique printing method. First, ensure optimal preparation of your design files; use high-resolution images and ensure proper color profiles for accurate reproduction on fabric. Second, the choice of ink and fabric is paramount; opt for high-quality, fast-drying inks compatible with DTF printing, and select fabrics that offer a smooth surface for best results.

When applying the print, consider even pressure distribution to prevent ink bleeding or uneven coverage. For dark fabrics, adjusting your design’s color balance can enhance contrast and vibrancy; lighter shades on darker materials tend to disappear faster, so a subtle approach is recommended. Conversely, for light fabrics, using a transparent base coat before printing can provide better opacity, ensuring the final print retains its brilliance.

DTF (Direct-to-Fabric) printing has emerged as a game-changer in the textile industry, offering vibrant and long-lasting results. By leveraging this innovative technology, experts recommend creating eye-catching designs that truly come to life on fabric. With its numerous benefits over traditional methods, DTF Fabric Printing is the preferred choice for achieving high-quality, visually stunning outcomes in various applications.